TOP-QUALITY TOOL MANUFACTURING.

Dihse+Avé is your reliable partner for tool- and mould making. Specialised in the production of injection-moulding and die-casting tools, our many years of experience and high-quality, comprehensive service are truly impressive.

Dihse + Avé – Tool Manufacturing

Need plastic parts with a requirement profile that cannot be covered by standard components? With the acquisition of the renowned toolmaking company Froede & Avé GmbH & Co. KG, we greatly expanded our competencies and capacities in the field of tool- and mould making for the production of customised injection-moulded parts. Benefit from injection moulding and toolmaking excellence all under one roof!

State-of-the-art manufacturing technology

Dihse+Avé GmbH & Co. KG offers state-of-the-art processing machines for the production of injection-moulding and die-casting tools. For over 40 years, the company has produced tools for the automotive and electrical industry and other consumer goods. Together with you, we’ll develop the perfect tool for your individual injection-moulding solution.

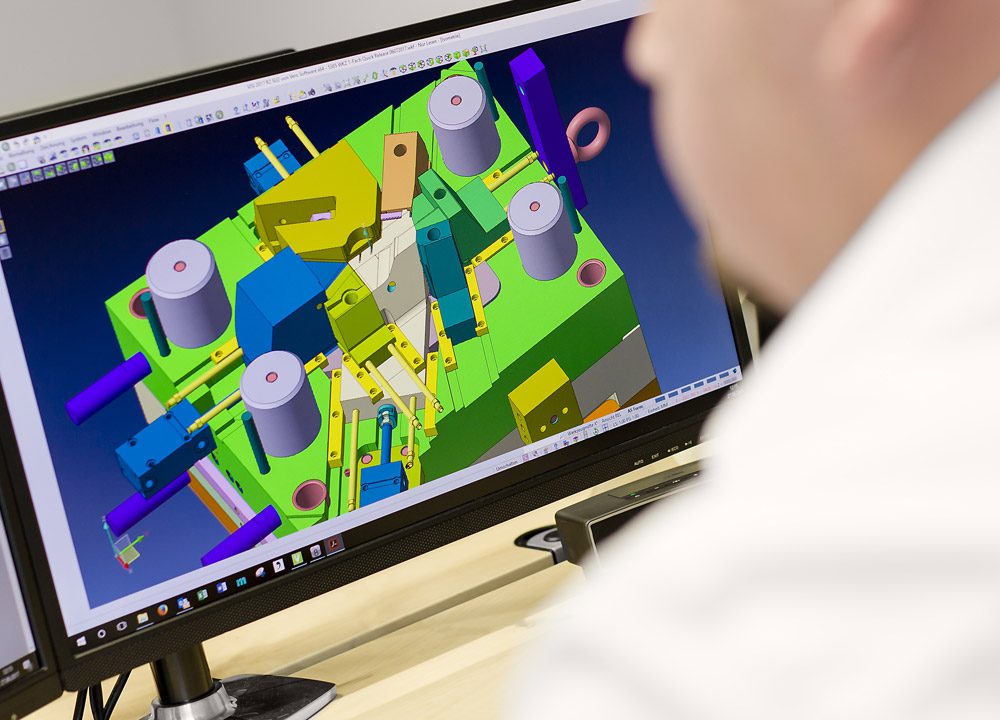

INDIVIDUAL CAD/CAM DESIGN.

CAD/CAM – 2D and 3D

Our experienced designers can design your tools in 2D and 3D – according to your specific wishes. Thanks to the latest CAD workstations and a large machine park, you can take advantage of outstandingly precise tools with short delivery times.

We work with the VISI design and NC programming system, which is connected directly to production and programming for 3D milling contours and 4-axis cutting programs. This allows us to import/export a wide range of data formats, such as Parasolid, IGES, CATIA VS, Pro-E, Siemens NX, STEP, Solid Works, Solid Edge, ACIS, DXF and DWG. Our qualified employees produce tools up to 1,000 x 600 mm in excellent quality – quickly, safely and flexibly.

Get in touch!

CUSTOMISED NEW TOOLS.

The high flexibility of our toolmaking allows for short implementation times for both new tools and for customer change requests.

Diverse

We develop and manufacture tools with free-form surfaces, 2-component tools, boring tools and tools for all injection-moulding manufacturing.

For large tasks

Our in-house 3 t crane system also enables the processing of large tool parts.

TOOL MAINTENANCE - FOR TIMELY PRODUCTION.

We service, maintain and repair our tools ourselves. Not just because we can, but above all, so that production deadlines can be reliably adhered to. Fixed service intervals and the use of state-of-the-art techniques for any necessary repairs also reduce downtimes to a minimum – of this you can be sure.

A BROAD RANGE FOR THE HIGHEST DEMANDS.

Every tool manufactured in house is tailor-made. Our know-how and modern machinery enable us to offer a broad range of services – including the following procedures for production technology:

Milling

CNC-controlled up to 1,000 x 600 mm

Die-sinking

4-axle CNC-controlled, up to 600 x 400 mm

Wire eroding

4-axle CNC-controlled, up to 370 x 245 mm

Turning

Cycle-controlled, Ø 160 x 750 mm

Surface grinding

up to 700 x 300 mm

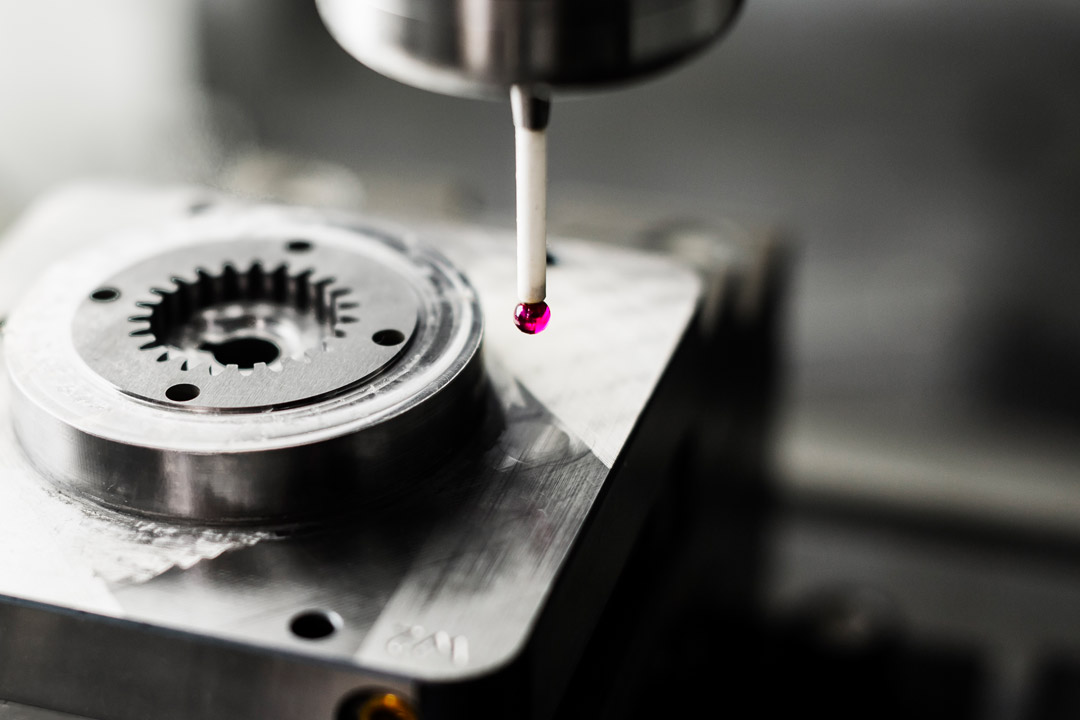

Measuring

Mitutoyo coordinate measuring device 700 x 500 x 400 mm

© 2024 Dihse GmbH